PCB Assembly

What is PCB Assembly?

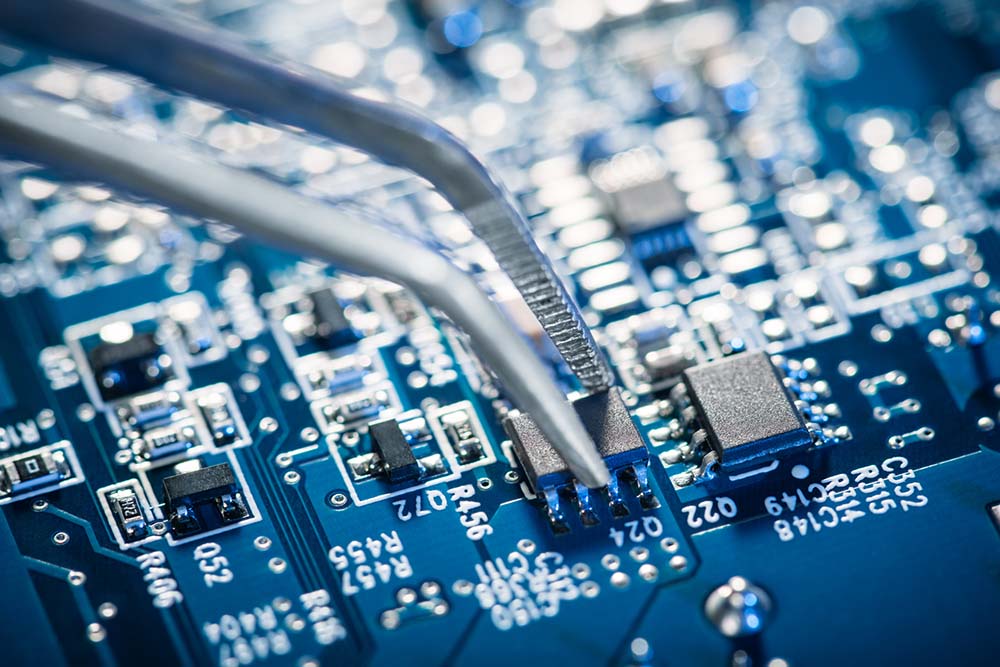

PCB assembly refers to the process of populating a printed circuit board (PCB) with electronic

components to create a functional electronic assembly. It involves soldering or mounting

components onto the PCB according to the design specifications.

How does PCB Assembly work?

Component Procurement : Source electronic components from reputable suppliers, ensuring

quality and compatibility with the design.

Stencil Creation and Solder Paste Application : Create stencils based on the PCB design

to accurately apply solder paste onto PCBs, facilitating component adhesion.

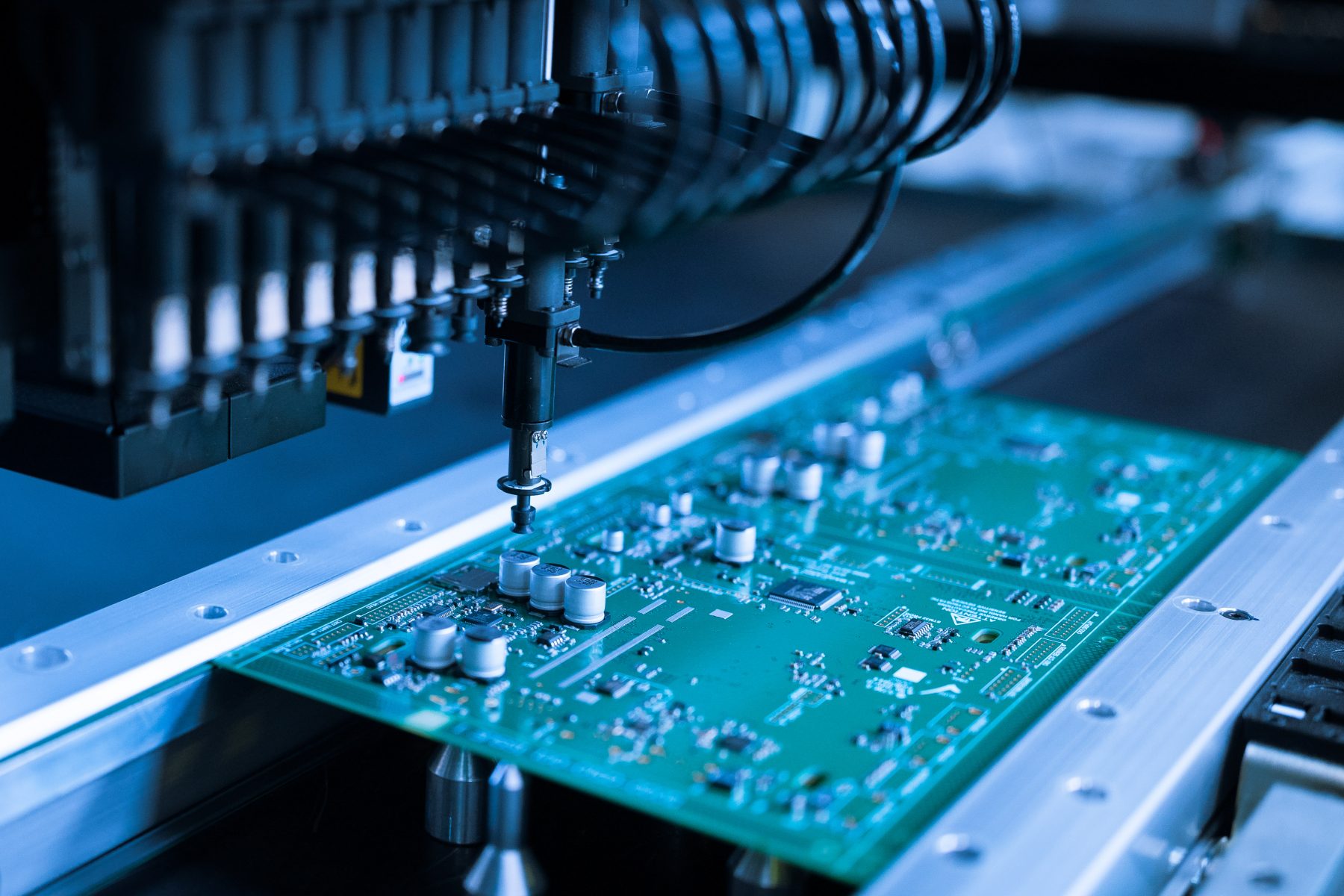

Component Placement : Utilize automated pick-and-place machines or manual labor to

precisely position components onto the PCB according to design specifications.

Reflow Soldering : Pass the PCB through a reflow oven to melt the solder paste, forming

secure bonds between components and PCB pads.

Inspection and Testing : Conduct visual inspection, automated optical inspection (AOI),

and functional testing to verify quality and functionality of assembled PCBs.

Why Choose Neural Circuits for your PCB Assembly?

Quality Assurance :

We uphold stringent quality standards throughout the PCB assembly process, ensuring the

reliability and functionality of your electronic assemblies.

State-of-the-art Facilities :

Our advanced manufacturing facilities are equipped with state-of-the-art machinery and

technology for precise and efficient PCB assembly.

Experienced Team :

Our team of experienced technicians and engineers has the expertise to handle complex PCB

assembly projects with precision and proficiency.

Customized Solutions :

We offer customization options to meet your specific requirements, including prototype assembly,

low to high volume production, and quick turnaround times.

Timely Delivery :

We are committed to delivering your PCB assemblies on time, helping you meet project deadlines

and objectives without compromise on quality.